Starting a deer processing business can be a lucrative venture, especially in regions with a strong hunting culture.

Whether you’re in Mississippi, Texas, South Carolina, or anywhere else in the United States, understanding the deer processing laws, setup, and the tools required are crucial for success.

We’ll cover everything from the average deer processing cost to the last step in deer processing, ensuring you’re well-equipped to process your own deer or start a full-scale deer processing plant.

Our Verdict

- Research your market: Identify the hunter population in your area, their processing needs (cuts, sausages, jerky), and existing competition.

- Invest in high-quality processing equipment.

- Choose a processing model: Decide between custom-exempt (processing individual deer for hunters) or USDA inspected (allows wider sales). Each has different regulations and costs.

- Focus on quality and hygiene: Invest in proper butchering tools, freezers, and maintain a spotless facility to ensure safe and delicious venison products.

- Explore alternative revenue streams: Offer processing of bones into pet chews, hides into leather goods (through partnerships with tanners), or tallow for rendering into soap or candles.

- Underestimate regulations: Research and comply with all state and federal regulations for licensing, inspections, and food safety protocols.

- Underestimate the cost and effort required for setup and maintenance

- Skimp on butcher training: Ensure your staff has proper training in deer butchering techniques to avoid meat waste and ensure quality cuts.

- Ignore the seasonal nature of the business and plan finances accordingly

- Forget marketing during the off-season: Offer processing workshops, sell hunting gear, or provide storage solutions for offseason.

Fast Fact: Which State is Leading the Deer Processing Industry?

Texas has the highest whitetail deer population in the United States, estimated at 5.3 million.

Following Texas, significant deer populations are found in Michigan, Alabama, and Mississippi, with their populations ranging from 1.5 to 2 million in each state.

This abundance makes Texas a prominent state for deer hunting.

In fact, whitetail deer are the most popular game animal in the United States. So it isn’t surprising that Texas topped the charts for the number of deer in 2017. The trend hasn’t dwindled over the years. And Texas continues to be the leading deer hunting state in the U.S.

Understanding the Market: Trends in the Deer Processing Industry

Before diving into the deer processing business, it’s essential to comprehend market demand.

Research the local hunting seasons and the popularity of deer hunting in your area. Knowing how much deer processors make on average can provide insight into the potential profitability of your venture.

Additionally, familiarize yourself with specific regional requirements, such as deer processing in Mississippi, Texas deer processing laws, and SC deer processing regulations.

Growing Demand for Specialty Products

The market is witnessing a surge in demand for specialty deer products, such as venison jerky, sausages, and other value-added products. This trend offers deer processors an opportunity to diversify their offerings and cater to a broader audience, including health-conscious consumers seeking high-protein, low-fat options.

Rise in At-Home Processing

With an increasing number of hunters looking to process their own deer, the demand for at-home deer processing tools and equipment has escalated. This trend underscores the need for businesses to offer not just services but also to retail processing equipment, kits, and educational resources such as deer butchering guides.

Regulatory Changes and Compliance

The industry is subject to state-specific regulations, such as Texas deer processing laws and SC deer processing regulations, which can significantly impact operations. There’s a trend towards stricter enforcement of sanitary standards and traceability, affecting how deer processing plants operate.

Technology Integration

Technological advancements are streamlining operations in deer processing plants, from inventory management to quality control. Businesses that leverage technology for efficiency, compliance, and customer service are gaining a competitive edge in the market.

Sustainability and Ethical Processing

There’s a growing consumer interest in sustainable and ethically processed meat. Deer processors that emphasize humane processing techniques and sustainable practices are more likely to attract a loyal customer base that is concerned about environmental and ethical issues.

Local and Organic Market Niches

Local and organic meat products continue to gain popularity, and deer meat is no exception. Processors offering locally sourced, organic deer processing services can tap into niche markets willing to pay a premium for these products.

Required Equipment and Average Cost

Starting a deer processing business requires a range of equipment to ensure the process is efficient, sanitary, and meets industry standards.

- Facility and Utilities

- Processing Building: Costs vary widely depending on size and location; average $20,000 $100,000.

- Refrigeration Units/Walk-in Cooler: Essential for storing carcasses; $5,000 $15,000.

- Freezers: For storing processed meat; $1,000 $3,000 each.

- Ventilation System: To maintain air quality and hygiene; $500 $2,000.

- Butchering Equipment

- Gutting Knives: For initial processing; $20 – $50 each.

- Boning Knives: For detailed meat separation; $30 – $60 each.

- Skinning Knives: Specialized for skinning; $25 – $50 each.

- Cleavers: Heavy-duty chopping; $50 – $100 each.

- Saw (Bone Saw or Bandsaw): For cutting through bone; $300 – $2,000.

- Grinders: For making ground meat; $500 – $2,500.

- Meat Slicers: For uniform cuts; $300 – $1,500.

- Meat Tenderizers: For improving meat texture; $150 – $600.

- Processing and Packaging Equipment

- Cutting Tables: Stainless steel for hygiene; $300 – $1,000 each.

- Hanging Scales: For weighing carcasses; $100 – $500.

- Butcher Blocks: For cutting meat; $100 – $500.

- Vacuum Sealers: For packaging meat; $200 – $1,500.

- Meat Wrapping Machines: For sealing packages; $500 – $2,000.

- Label Printers: For product labeling; $300 – $1,000.

- Packaging Materials: Vacuum bags, butcher paper, labels; $500 – $1,000 (initial stock).

- Cleaning and Sanitation

- Hand Washing Stations: Essential for hygiene; $200 – $600 each.

- Sterilizers: For sanitizing knives and tools; $100 – $500.

- Cleaning Supplies: Detergents, sanitizers, brushes; $200 – $500 (initial stock).

- Aprons and Gloves: For personal protection; $50 – $200 (initial stock).

- Transportation

- Refrigerated Truck or Trailer: For transporting meat; $10,000 – $50,000.

- Non-refrigerated Truck or Trailer: For other transportation needs; $5,000 – $25,000.

- Office Equipment

- Management System and Software: For record-keeping and management; $500 – $2,000.

- Cash Register or POS System: For sales transactions; $300 – $1,500.

- Office Supplies: Paper, pens, etc.; $100 – $300.

- Miscellaneous

- Deer Hoist and Gambrel: For hanging deer during processing; $50 – $200.

- Scales: For weighing packaged products; $50 – $200.

- First Aid Kit: For workplace safety; $50 – $100.

Summary of Average Costs

- Facility and Utilities: $26,500 – $119,000

- Butchering Equipment: $1,845 – $6,460

- Processing and Packaging Equipment: $2,200 – $7,500

- Cleaning and Sanitation: $550 – $1,800

- Transportation: $15,000 – $75,000

- Office Equipment: $900 – $3,800

- Miscellaneous: $200 – $500

- Total Estimated Startup Cost: $47,195 – $214,060

These costs can vary greatly depending on your specific needs, location, and scale of the business. It’s essential to conduct a detailed business plan and cost analysis tailored to your circumstances before starting the business.

Calculate your business expenses here:

Budget Calculator

Understanding the Market: Industry Statistics

As reported by Global Markets Insights, “Meat Processing Equipment Market size is anticipated to expand at 4.5% CAGR from 2024 to 2032, owing to the technological advancements.”

This also indicates an increase in demand for deer processing.

Industry Growth and Value

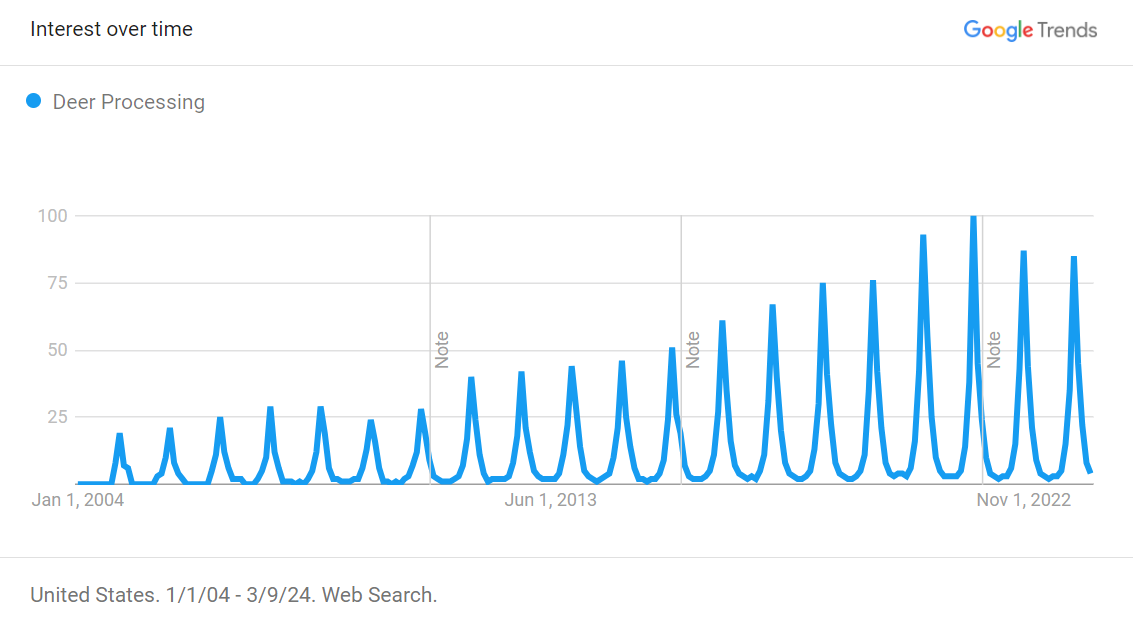

The deer processing industry, closely tied to hunting seasons and populations, has seen fluctuating growth rates. For example, in states with robust hunting cultures, the industry can experience significant seasonal spikes. The overall value of the industry is also influenced by trends in meat consumption, with venison being increasingly recognized for its health benefits.

Average Deer Processing Costs

As of the latest data, the average cost for processing a deer can range significantly, from $75 to $200 or more, depending on the complexity of services (e.g., basic butchering vs. making sausages, jerky, and other processed products). This variance highlights the potential for profit margin optimization through service diversification.

Profitability and Revenue

Deer processors’ profitability can vary widely, with annual revenues ranging from tens of thousands to over a hundred thousand dollars, depending on the scale of operations and service offerings. Factors such as processing efficiency, cost management, and value-added services play critical roles in determining profitability.

Demand Indicators

The demand for deer processing services correlates strongly with deer hunting licenses issued annually. For instance, states like Mississippi, Texas, and South Carolina, known for their active hunting populations, have seen steady or increasing license sales, indirectly indicating a stable or growing demand for deer processing services.

Setting Up Your Deer Processing Business

The deer processing setup involves several critical steps. First, you need to secure a location that complies with local zoning laws and has enough space for your processing plant. Next, understanding what you need to process a deer is vital.

This includes acquiring the necessary deer processing tools and equipment, which can be bought new or used to reduce initial costs.

Choosing the Right Business Structure

Choosing the right business structure for a deer processing business often depends on factors like liability, taxation, and operational flexibility. To get better guidance on which structure to choose, you should consider hiring a business formation service.

An LLC (Limited Liability Company) is commonly recommended because it offers personal liability protection to owners, ensuring personal assets are safeguarded from business debts or legal issues.

It also allows for flexible profit distribution among owners and can be taxed as a sole proprietorship, partnership, or corporation, providing significant tax advantages.

This flexibility and protection make the LLC structure particularly appealing for deer processing businesses, balancing the need for legal protection with the benefits of tax efficiency.

Home-based Deer Processing Businesses

- When establishing a home-based deer processing business, zoning laws are crucial, as residential areas may have restrictions on commercial activities.

- Compliance with health and safety regulations ensures the workspace meets sanitary standards, which is crucial for food handling businesses.

- This might include installing proper refrigeration, ensuring clean working surfaces, and managing waste efficiently to minimize environmental impact.

- Securing the necessary permits is also essential, as it legitimizes the business in the eyes of regulatory bodies. Consulting with legal and financial advisors can provide guidance on navigating these requirements effectively.

- Effective management for a home-based deer processing business involves organizing your workspace efficiently, adhering to strict hygiene and safety standards, and maintaining accurate records of your operations and finances.

- Networking with local hunters and suppliers can also provide valuable support and growth opportunities.

Deer Processing Equipment and Tools

Investing in high-quality deer processing equipment is crucial for efficient and safe operations. The essential tools include knives, saws, grinders, and packaging supplies.

For those interested in deer processing at home, there are smaller-scale tools and equipment available that are designed for personal use.

Always ensure that your equipment meets the local deer processing laws and regulations to avoid any legal issues.

Here’s a summary of the necessary tools and equipment you should consider for your deer processing business.

- Quality Knives and a Bone Saw: The foundation of any deer processing setup. Quality blades ensure clean cuts and reduce the risk of accidents. A bone saw can be useful for more challenging cuts and for removing the skull plate if you plan on mounting the animal.

- Meat Grinder and Sausage Stuffer: A meat grinder is indispensable for processing venison into ground meat for various dishes. Consider investing in a durable, commercial-grade grinder for long-term use. A sausage stuffer is also a key piece of equipment if you plan to make sausages, allowing for efficient processing and a variety of sausage types.

- Vacuum Sealers: Essential for preserving meat’s freshness and extending its shelf life. Vacuum sealing prevents freezer burn and maintains meat quality. You might choose between chamber sealers for heavy-duty use or suction-style sealers for more occasional needs.

- Food Dehydrator and Jerky Shooter: If making venison jerky is part of your plan, a food dehydrator will be a useful tool. Jerky shooters help in efficiently preparing meat for dehydration, whether you prefer sticks or strips.

- Meat Slicer: While not essential for everyone, a meat slicer is useful for preparing evenly sliced meats for jerky, roasts, and more. It offers precision that can be difficult to achieve with a knife alone.

- Coolers, Butcher Kits, and Meat Lugs: Coolers are vital for cooling down the meat immediately after processing, while an all-in-one butcher kit ensures you have all the necessary tools on hand. Meat lugs are useful for meat transfer and storage during processing.

- Digital Scale: Important for measuring precise amounts of meat for recipes, ensuring consistent quality and taste in your products.

- Freeze Dry Machine: Although not commonly found in all processing setups, a freeze dry machine can significantly extend the shelf life of your products, offering a unique value proposition for your business.

Remember!

When selecting equipment, consider not only the cost but also the safety, maintenance, durability, and the specific needs of your operations.

It’s wise to invest in high-quality equipment that will serve you well over the years, even if it means a higher initial outlay.

Equipment durability, ease of cleaning, and efficiency should guide your purchasing decisions.

Starting with the essentials and gradually building up your collection of tools as your business grows and as needs become apparent is a practical approach.

This staged investment allows you to spread out costs while still maintaining the capability to deliver high-quality processed deer meat.

Meat Storage, Packaging, and Processing

Meat should be stored at 0°C to 2°C to maintain flavor and moisture, with coolers designed to circulate cool air effectively.

For packaging, vacuum sealing is recommended to prevent drying, spoilage, or freezer burn, with vacuum-packed or tightly wrapped meat for freezer storage.

For detailed procedures and equipment recommendations, refer to the source at opentextbc.ca.

Processing Meat

Processing regulations in the food industry, such as SOPs (Standard Operating Procedures), SSOPs (Sanitation Standard Operating Procedures), and HACCP (Hazard Analysis Critical Control Points), are crucial for ensuring food safety and quality.

SOPs provide detailed instructions on how to perform specific operations to maintain consistency and compliance.

SSOPs focus on maintaining hygiene and sanitation throughout the production process to prevent contamination.

HACCP is a management system that addresses food safety through the analysis and control of biological, chemical, and physical hazards from raw material production, procurement, and handling, to manufacturing, distribution, and consumption of the finished product.

These regulations and systems are designed to prevent food safety hazards and ensure that food products are safe for consumption.

Legal Considerations and Regulations

Navigating the deer processing laws is a critical aspect of your business setup. Each state, such as Texas and South Carolina, has its own specific deer processing regulations that must be followed.

These laws can cover everything from sanitation standards to licensing requirements.

It’s also important to understand the deer butchering guide provided by local wildlife agencies to ensure that your processing methods are compliant.

Licenses Needed For Deer Processing Businesses

- State-Specific Regulations and Licenses: Each state has its own set of laws and regulations regarding the sale and distribution of deer meat, hides, and antlers. It’s crucial to consult with your state’s Department of Natural Resources or Fish and Wildlife Services to understand what specific licenses and permits are required for deer processing in your area.

- USDA Requirements: The United States Department of Agriculture (USDA) enforces the Federal Meat Inspection Act, which applies to meat processors. To sell your products across state lines or for export, your facility must pass USDA inspection.

This involves demonstrating compliance with standards for sanitation, humane animal handling, and product safety. The USDA’s Food Safety and Inspection Service (FSIS) conducts these inspections. - Minnesota Example – “Equal To” USDA Inspection Program (E2 Inspection): For businesses operating within a single state, such as Minnesota, there’s an option to participate in the state’s Meat and Poultry Inspection (MPI) program, considered “Equal To” the federal standards. This program allows slaughter and processing establishments to sell, distribute, and wholesale their products within the state. These establishments undergo continuous inspection to ensure they produce safe food, similar to federal inspections.

The E2 program is a great example of how state-level programs can offer a pathway for smaller businesses to operate within regulatory frameworks. - Continuous Inspection: It’s important to note that continuous inspection is a requirement for businesses that wish to sell their products to retail outlets. This means your process will be inspected daily during operations to ensure compliance with food safety standards. The type of inspection—federal or state—will determine where you can sell your products.

Other Permits

To operate a deer processing business, in addition to the previously mentioned federal and state meat processing licenses, there are several other permits and licenses you may need depending on your business activities, location, and the specific requirements of local and federal governing bodies.

- Federal Licenses and Permits: If your business activities are regulated by a federal agency, you will need the corresponding federal license or permit.

For example, if you plan on importing or transporting animals or animal products across state lines, you’ll need to check with the U.S. Department of Agriculture (USDA).Similarly, if your business involves the sale of alcoholic beverages, you’ll have to obtain permits from the Alcohol and Tobacco Tax and Trade Bureau (TTB) as well as your local Alcohol Beverage Control Board.

You’ll also need to get a Federal Employer Identification Number (EIN), issued by the IRS to businesses for tax purposes.

- State and Local Requirements: In Texas, for instance, licenses and permits for food manufacturing, wholesaling, or distributing are managed by the Department of State Health Services.

For meat and poultry processing specifically, you’d need to refer to the state’s meat safety assurance unit for licensing applications and information.

Retail food establishments have their own set of requirements and must contact the local health department or refer to the state health services for guidance. Milk and dairy product regulations are also covered under specific state guidelines.

Important Considerations

It’s important to start considering licensing and permitting early in your business planning process, as obtaining a license or permit can take anywhere from 4 to 8 weeks, and in some cases, it may involve a pre-inspection of your facility.

The specific licenses and permits needed can vary significantly by location and the nature of your business activities, so you should consult the appropriate local and federal agencies for the most accurate and up-to-date information.

This process ensures that your business complies with all necessary health, safety, and operational standards.

For more detailed information and to apply for the necessary licenses and permits, you should visit the websites of the relevant federal and state agencies or contact them directly via phone.

Marketing Your Deer Processing Business

To attract clients, consider unique selling propositions such as offering “Southern Spice Deer Processing” services or specializing in “At Home Deer Processing” packages for DIY enthusiasts.

Effective marketing strategies can include creating a website, leveraging social media, and engaging with the local hunting community.

- Leverage Social Media: Use platforms like Facebook and Instagram to showcase your work, share customer testimonials, and post engaging content related to deer processing.

- Engage with the Local Hunting Community: Attend local hunting events, sponsor competitions, or offer workshops on deer processing to build relationships.

- Offer Referral Discounts: Encourage word-of-mouth marketing by providing discounts or incentives to customers who refer new clients.

- Create a Professional Website: Include detailed service descriptions, pricing, customer reviews, and an easy booking system.

- Collaborate with Local Businesses: Partner with hunting stores, outdoor gear shops, and local clubs for mutual promotion.

- Email Marketing: Send newsletters with seasonal tips, special offers, and updates about your services to keep your business top-of-mind.

- Focus on Quality and Unique Services: Highlight any specialty services like organic processing methods or custom cuts to differentiate from competitors.

- Customer Service Excellence: Ensure a great customer experience to encourage repeat business and positive reviews.

Cost Considerations

Understanding the average deer processing cost is crucial for setting competitive prices while ensuring profitability.

Prices can vary based on the services offered, such as basic butchering or additional options like making sausages or jerky.

Keep in mind that the initial investment for deer processing equipment for sale can be significant, but it’s a necessary expense for providing quality services.

Funding

To start a deer processing business, securing funding is essential for various initial expenses.

- Small Business Loans: Banks and credit unions offer loans specifically designed for small businesses, providing the necessary capital for equipment, leasing, or renovating facilities.

- Agricultural or Small Business Grants: Look into grants from governmental and non-profit organizations that support agricultural initiatives or rural businesses. These grants often target specific sectors and can provide funds without the requirement to repay.

- Crowdfunding Platforms: Utilize platforms like Kickstarter, Indiegogo, or GoFundMe to raise funds by pitching your business idea to the public. This method can also serve as a marketing tool, generating interest and potential customers.

- Personal Savings: Investing personal savings into your business provides full control without the need to repay a loan or answer to investors, though it does come with personal financial risk.

- Angel Investors: Individuals or groups interested in investing in startup businesses in exchange for equity. They can provide not only funds but also valuable advice and industry connections.

- Government Programs: Federal and state government programs may offer loans, grants, or support services for startups, especially those in agriculture or contributing to rural economies. The USDA, for example, has various programs supporting meat processing facilities.

Each funding source has its advantages and requirements, so it’s important to carefully consider which option best aligns with your business plan and goals.

Budget for Starting Deer Processing Business

Starting a deer processing business involves costs like purchasing equipment, which could range from $5,000 to $20,000 for basic to advanced setups, renovating or preparing a facility, that might cost $2,000 to $50,000 depending on the scale and condition, and licensing and insurance fees, which could be a few hundred to a couple of thousand dollars.

While specific budgets can vary widely based on location, size, and services offered, initial costs can range from $10,000 to over $100,000.

This includes processing equipment, refrigeration, facility renovation, and compliance with health and safety regulations.

Researching local competition is crucial to understanding pricing strategies and market demand. Prices for services can vary, influencing your budget planning.

For detailed estimates tailored to your business plan, consulting with industry experts and financial advisors is recommended.

For a better result, calculate your business expenses here:

Budget Calculator

FAQs

1. How much do deer processors make?

According to ZipRecruiter, “the average hourly pay for a Deer Processing in the United States is $24.67 an hour.”

The income for deer processors can vary widely based on factors such as location, volume of business, and the range of services offered. Deer processors can potentially make a significant income during the hunting season, especially in areas with high deer populations and demand for processing services.

2. What do you need to process a deer?

To process a deer, you need a variety of tools and equipment, including sharp knives for skinning and butchering, a bone saw for cutting through bone, a meat grinder for making ground meat products, and a workspace that complies with sanitary standards.

Other essentials include a large cutting board, meat hooks, a weighing scale for accurate meat distribution, and packaging supplies for storing the processed meat.

Proper knowledge of deer anatomy and butchering techniques is also crucial for efficient and humane processing.

3. What market trends impact the deer processing industry?

Increasing demand for specialty deer products and a rise in at-home processing are notable trends.

4. How does one comply with deer processing regulations?

Familiarizing yourself with and adhering to state-specific regulations, such as those in Mississippi, Texas, and South Carolina, is essential.

5. What equipment is necessary for starting a deer processing business?

Key tools include knives, saws, grinders, and packaging supplies, with options for both commercial and home processing setups.