Our Verdict

- Sample other homemade salsa sold at grocery stores or farmer's markets.

- Formulate a unique recipe and label it.

- Get a license and contact the right people. Finding the right partners might take some pitfalls, but start small and stay consistent.

- Be transparent with your work process and contact legal authorities for information and guidance.

- Budget your business decisions according to your profits and capital.

- Monitor consumer behavior once you start selling.

- Make educated decisions when scaling up.

- Steal a recipe and rebrand it.

- Go big from the get-go. The food industry can be brutal.

- Compromise on marketing your product.

- Start making salsa in bulk right from the start.

- Compromise on proper labeling and preservation.

How Big is the Salsa Industry?

According to a report by IBISWorld, salsa “Industry revenue has been growing at an average annualized 0.4% over the past five years”. The revenue was expected to total $954.5 million in 2023, with an estimated jump of 1.2%.

The industry has stable growth in 2024 and is likely to continue growing. Despite many big names in the salsa industry, there is still room for new entrants.

The rising trend in the salsa industry is towards vegan salsa. Other variations such as gluten-free, vegetarian, and plant-based salsa have a stable trend as well.

That said, the food industry is saturated, and careful planning is needed to establish a name. Starting small is vital to making a stable entry into the salsa industry.

Getting started can be daunting, but here are some steps you can take to ensure you have all the fundamentals right.

Required Equipment and Average Cost

Starting a salsa business requires a variety of equipment for production, packaging, and distribution. Here’s a comprehensive list along with estimated average costs:

Production Equipment

- Industrial Blender or Food Processor

Average Cost: $1,000 – $3,000

Purpose: To blend ingredients to the desired consistency.

- Cooking Kettles or Pots

Average Cost: $200 – $1,000 each

Purpose: For cooking the salsa.

- Commercial-Grade Stove or Hot Plate

Average Cost: $1,000 – $3,000

Purpose: For cooking the salsa.

- Cutting Boards and Knives

Average Cost: $50 – $200

Purpose: For chopping ingredients.

- Mixing Bowls

Average Cost: $20 – $100 each

Purpose: For mixing ingredients.

- Measuring Cups and Spoons

Average Cost: $10 – $50

Purpose: For accurate ingredient measurement.

Packaging Equipment

- Glass Jars or Plastic Containers

Average Cost: $0.50 – $2.00 each

Purpose: For packaging the finished salsa.

- Lids and Seals

Average Cost: $0.10 – $0.50 each

Purpose: To seal jars and maintain freshness.

- Label Printer

Average Cost: $300 – $1,000

Purpose: For printing product labels.

- Labels

Average Cost: $0.10 – $0.50 each

Purpose: For product identification and branding.

- Shrink Bands or Tamper-Evident Seals

Average Cost: $0.05 – $0.20 each

Purpose: To ensure product safety.

Storage Equipment

- Refrigeration Units

Average Cost: $1,000 – $5,000

Purpose: To store perishable ingredients and finished products.

- Shelving Units

Average Cost: $100 – $500 each

Purpose: For storing jars and ingredients.

Quality Control and Testing

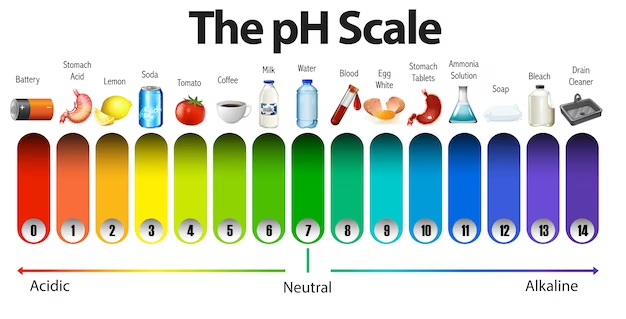

- pH Meter

Average Cost: $50 – $200

Purpose: To ensure the acidity level is safe for preservation.

- Thermometer

Average Cost: $20 – $100

Purpose: For monitoring cooking temperatures.

Miscellaneous Equipment

- Sanitizing Equipment

Average Cost: $100 – $500

Purpose: For ensuring all equipment is properly sanitized.

- Work Tables

Average Cost: $200 – $1,000

Purpose: For food preparation and packaging.

- Personal Protective Equipment (PPE)

Average Cost: $50 – $200

Purpose: For ensuring hygiene standards (e.g., gloves, hairnets).

Office Equipment

- Computer and Hardware

Average Cost: $500 – $2,000

Purpose: For managing business operations and finances.

- Office Furniture

Average Cost: $200 – $1,000

Purpose: For administrative tasks. - Management Software

Average Cost: $500 – $600

Purpose: For inventory management and official records

Marketing and Distribution

- Website Development

Average Cost: $500 – $5,000

Purpose: For online presence and sales.

- Business Cards and Flyers

Average Cost: $100 – $500

Purpose: For marketing and networking.

- Vehicle for Distribution

Average Cost: $10,000 – $30,000 (if applicable)

Purpose: For delivering products to retailers or customers.

Initial Inventory and Ingredients

- Fresh Produce and Spices

Average Cost: $500 – $2,000 (initial stock)

Purpose: For making the salsa.

Legal and Compliance

- Licenses and Permits

Average Cost: $200 – $1,000

Purpose: To legally operate the business.

- Insurance

Average Cost: $500 – $2,000 annually

Purpose: For liability and product insurance.

Estimated Total Cost

- Low-end: Approximately $20,000

- High-end: Approximately $70,000

These costs can vary significantly based on location, scale of operations, and specific business needs. It’s important to conduct thorough research and create a detailed business plan to estimate your specific requirements and costs accurately.

Develop Your Salsa Recipe

To start a salsa business, the first thing you’ll need is a stellar recipe for salsa. There are many variations to go with.

Pretty much any Mexican restaurant you’ve been to has its own salsa recipe. Yet, nothing quite stands up to your grandmother’s salsa, does it?

That’s just how many choices there are.

Classically, there are about a dozen types of salsa. If you’re going with multiple recipes, you should categorize them into these types.

Some of the classic salsa types are:

- Pico de Gallo

- Salsa Taquera

- Salsa Roja

- Salsa Verde

- Salsa de Aguacate

- Salsa Criolla

Alternatively, name your own unique salsa recipe if you don’t have different types.

Developing your recipe means figuring out just the right amount of ingredients for every batch. Figures are essential to keep a consistent taste, a necessary factor for retail.

Preserving and Refrigeration

Keep in mind that your salsa is homemade. It’s much more organic than those big labels. And that’s what makes it challenging to handle.

Preservatives and refrigeration change the taste by a considerable amount. Your salsa may differ in taste by the time it reaches the taster. It would be best to consider which preservatives are safe with the ingredients in your salsa.

Keeping track of the time it is kept in storage is essential.

A good way would be to create a jar of salsa, store it, and monitor the taste differences.

There are both artificial and natural preservatives. Since your salsa is homemade, you can simply rely on lemon juice or vinegar. You’ll need to determine the correct quantities for every batch because you don’t want to pump an unhealthy amount of citric acid into your food.

The pH of your salsa shouldn’t be more than 4.6. It should preferably be below 4.0.

Tomatoes get more acidic as they are cooked. To maintain lower acidity, it is recommended to cook them for as little time as possible. While salsa doesn’t always need to be cooked, it is better to cook it if you want it to last longer.

Remember that vinegar and lemon juice don’t go in the same quantity. Both impact the taste differently, since vinegar is more acidic than lemon juice.

Learn more about preserving your salsa based on your ingredients before canning it.

Finding a Commercial Kitchen

For huge batches, your home kitchen may not suffice. A commercial kitchen in your area will help you with that.

Commercial kitchens are equipped with all the tools you’ll need to effectively maintain that good taste. They also have ample storage and refrigeration.

This also depends on how big the kitchen is. Finding one that is suitable for your needs is essential.

That said, remember that renting a commercial kitchen can be costly. If you’re on a tight budget, you’ll need to look for an alternative.

You’ll likely want to rent it when you’ve made some sales.

Another advantage of commercial kitchens is the transparency they provide to the system. They are effective in helping you check quality. We’ll explore quality checks in a bit.

Commercial kitchens are a great option if you don’t have space in your home. To keep track of your business, you can set up a virtual office without having to remodel your house. This way you can optimize your business operations without worrying about having a dedicated building.

Develop Your Label

Your label should be distinct and easy to remember. Something witty will attract people and make you stand out.

While working on your label, you might feel overwhelmed by the number of names the salsa industry has.

With so many varieties of salsa, if you’ve got something unique to offer, you should incorporate that into your label.

That said, labels aren’t just an image. Depending on where you’re selling, you’ll be required to get a UPC label.

UPC Label

UPC label is the barcode label you see on products bought from stores. If you’re selling your homemade salsa door-to-door, you won’t need a barcode label.

However, at some point in your business, you’ll likely start selling to stores. You’ll need a UPC label, then.

UPC labels aren’t free, but many local stores will allow cheaper repurchase barcodes. You should look into UPC labels and ask the stores before purchasing.

When you expand to bigger stores, you’ll likely need to upgrade your labels as well. GS1 provides all barcodes in the US. Or rather, it provides licenses to all businesses for a specific number of barcodes.

You’ll need to apply for the GS1 Company prefix to get the license.

Nutritional Analysis

It isn’t mandatory to get a nutritional analysis for small home-based businesses. Obviously, you won’t need it for something like a farmer’s market.

That said, make sure you have an accurate ingredient statement. Once you begin to expand, this statement will matter for quality control.

Even from a customer perspective, it gives you transparency and builds credibility.

It is an excellent practice to get it done once you scale up. It is mandatory to get a nutritional analysis if you are registered with the FDA. Most prepared foods must have proper and accurate nutritional and allergen labeling.

For a proper nutritional analysis, you can hire a commercial food lab to get your salsa analyzed.

Alternatively, you can refer to USDA’s Food Nutrient Database to calculate appropriate nutrient information based on your recipe.

Laws and Regulations Concerning Food Selling

As a food business, you’ll need licenses and permits to operate. State-wise laws may differ. And you’ll want to look into them before you start retail. Check cottage food laws in your state to be sure.

For starters, you’ll need a license to start a salsa business. Your local health department should be able to give you a permit. Depending on state regulations, a license can range from $100 to $1000.

With this license, you should be able to sell in the local market. Unless you’re thinking of crossing the border, the license will suffice.

To be sure of other food-related regulations, check out the FDA’s regulation guidance.

FDA does not regulate small scale food businesses such as farmer’s markets, restaurants, grocery stores, food trucks, cafeterias, etc. These business bodies are regulated by local and state governments.

Home-based businesses don’t need to be registered with the FDA. Local health agencies inspect these food services instead.

Study FDA regulations to understand what classifies as a home/private residence to ensure you follow the correct guidelines.

If you intend to operate as a full-fledged business, you’ll need to register your business and get an EIN. An Employer Identification Number is assigned by the IRS and identifies your business for tax purposes.

Quality Control and Consistency

As we mentioned before, commercial kitchens help you maintain a quality standard.

They keep the process systematic and help you plan things right. If you’re just starting your salsa business, you might not need an extensive facility.

But you won’t forever be running your business alone. Once you get kitchen personnel, things must be kept in proper check and balance.

You’ll want to ensure the recipe acts as a formula so that every batch and delivered product has a consistent taste.

Somewhere down the road, you should get a business appraisal or a certification. Maintaining good working conditions is critical to improving food quality.

For food inspection, you can check the AFDO’s directory of state and local officials that provides information regarding food-related authorities in all the states.

Packaging and Bottling

You won’t forever be bottling salsa by hand. But don’t worry. You won’t need huge machinery to start a salsa business. You can get small-scale bottling machines to do this.

You can look around for providers to buy glass jars in bulk for bottling your salsa. Choose the right size and quantity depending on demand.

Keep in mind the many health concerns that come with bottling. Make sure the salsa is cooked before it is canned. The preservatives you are using will also affect the salsa once you’ve bottled it. If you notice mold or a change in color on the top, or if the salsa doesn’t smell the same after you’ve stored it, you are likely doing it wrong.

Make sure you store the salsa properly after bottling it. If you want to avoid the hassle of packaging your salsa, you can also hire a contract packager. Contract packagers, also caller copackers, also ship and deliver.

Depending on your area, the price may vary. But it’ll save you the trouble of getting bottling equipment and accessories yourself.

Finding the Right Audience

Finding the right people to sell your salsa can be challenging. Try to look for places where other people are selling their products.

Farmer’s market would be an excellent start. You’ll want to contact your local stores and ask if you can sell there.

Other than that, small eateries, local hotels, and restaurants are an excellent way to get your salsa circulating.

Local food fests, grocery stores, and malls are good places to sell, too.

However, before placing your salsa anywhere, make sure it’s shelf-stable. After testing for shelf-stable salsa, you’ll need a ‘Scheduled Process’ label from a food lab.

Otherwise, you’ll want to stick to the farmer’s market or direct orders through your online marketplace.

It won’t be free, but it might save you some trouble. With online selling, you can sell on marketplaces or create your own e-commerce website.

Once you’ve started selling, you can approach bigger stores and supermarkets.

Marketing

Regardless of how good your salsa is, it won’t sell if people can’t find it.

Running online marketing campaigns is a great way to get attention. If you’ve set up an online store, that’ll go hand in hand with your campaign.

If not, you can still use social platforms to push your product into the market.

If you’re just starting out, you can try going door-to-door and offering samples. It’s a traditional method of marketing, but it is still effective.

Once you’ve built up a bit of an audience, you can even invest to run ads and reach more people.

Budget

Making the right decisions is essential for tight budgets.

Luckily, making salsa isn’t costly. But making a business out of it can be.

You could get your pantry items from a local grocer. Setting up a deal with a supermarket might get you a business discount.

Before deciding, try different providers before settling on one that suits you both location-wise and financially.

Depending on size, a commercial kitchen can cost $15 to $30 per hour. If you’re renting a big one, it can be as high as $75 per hour.

The people you bring on board are a separate matter. Most homemade products are sold by family businesses. Otherwise, you’ll need to bring more crew.

Bottling and equipment can cost variably anywhere from as low as $2000 to as high as $30,000. This depends on your monthly sales as well. A pallet of bottles can cost as much as $3000, but you might not sell out in a month or may sell out even more.

Similarly, bottling equipment can vary in price based on scale.

Marketing campaigns can be costly if you’re hiring someone to do it. Online marketplaces require a fee to set up stores, too. Publicizing could cost upwards of $5000 per month.

The total budget will depend on your choices and the scale of your business.

For a better result, calculate your business expenses here:

Budget Calculator

Scaling Up

If you’re selling your salsa for quick profits and aren’t looking to become a huge brand, that’s fine. Sticking to local markets builds a loyal consumer base and keeps processes manageable.

If you’re willing to scale up and go big, you’ll likely need to keep expanding.

Registering your business, hiring personnel, upscaling your financial plan, and getting legal advice would prove to be helpful. You should opt for a suitable business structure while you’re at it. Usually, an LLC is the preferred option.

Regardless of what you choose, make sure you maintain the quality of your business.

Some things you want to make sure of while thinking of going big are:

- A UPC label

- A nutritional analysis

- A dedicated kitchen, either owned or leased

- Proper equipment and crew

- Risk analysis and safety measures

- Large-scale delivery and packaging equipment

- FDA approval

Food Testing

To prevent factors such as time and preservation from affecting the taste of your salsa, there are ways to incorporate longer-lasting flavors.

In some cases, you’ll need to head to a food lab and experiment to find out the right ingredients.

Don’t think that you’re pumping the food with chemicals. A small amount of preservative is needed to keep food fresh and safe from mold.

While selling, you’ll need to ensure the smell, freshness, and taste aren’t lost. Food labs can help you figure out the right formula. You’ll also want to make sure your salsa doesn’t contribute to any health concerns or if it has a possible allergen.

Homemade Salsa Business Plan

When you’re starting your home business selling salsa, a robust business plan will come in handy. Make sure you’ve got the following points covered:

1. Business Concept

- Unique Selling Proposition (USP): Highlight your salsa’s unique flavors or ingredients.

- Brand Story: Share the inspiration behind your salsa.

2. Market Analysis

- Consumer Trends: Identify popular salsa trends and preferences.

- Competitive Analysis: Compare your salsa’s strengths against competitors.

3. Product Development

- Flavor Innovation: Offer seasonal or unique flavors.

- Ingredient Sourcing: Use fresh, high-quality ingredients.

4. Business Operations

- Sustainable Practices: Implement eco-friendly packaging.

- Quality Control: Ensure consistent taste and safety.

5. Marketing Strategy

- Community Engagement: Partner with local events or markets.

- Content Marketing: Share recipes and behind-the-scenes content.

- Influencer Partnerships: Collaborate with food influencers.

6. Sales Channels

- Direct Sales: Consider online sales or subscription models.

- Retail Partnerships: Approach local stores and markets.

7. Financial Plan

- Break-Even Analysis: Calculate sales needed to cover costs.

- Funding: Explore crowdfunding or loans if needed.

- Cost Control: Find ways to reduce expenses.

8. Regulatory Compliance

- Local Regulations: Adhere to food safety laws.

- Labeling Requirements: Ensure accurate product labeling.

9. Growth and Scaling

- Expansion: Plan for new markets or product lines.

- Partnerships: Seek collaborations with restaurants or retailers.

10. Risk Management

- Product Recalls: Have a recall plan in place.

- Supply Chain: Identify backup suppliers.

- Crisis Management: Prepare for potential challenges.

Important Considerations

There are many things to consider when it comes to selling salsa.

- Check out the salsa in stores and restaurants around you. See what’s popular and what you could do to bring a better taste to the market.

- Ensure you aren’t using any ingredients that can cause health issues.

- Enlist the ingredients accurately to make sure allergens can be identified.

- Make sure work conditions are safe and clean.

- Budget your plans according to the profits. Selling salsa can be challenging in the beginning. Your first goal should be to get orders under your belt.

FAQs

1. Can I make and sell salsa without renting a commercial kitchen?

Yes. You don’t necessarily need to rent a commercial kitchen to start a salsa business. Instead, to handle your product, you can hire a co-packer.

However, you will need storage space, like refrigeration, for your salsa if it isn’t shelf-stable. If you don’t have that sort of space in your home, a commercial kitchen might be your best option.

2. How much does it cost to make salsa?

Making a batch of salsa at home is cheap and will cost around $2. This depends on where you get your sources and what you put into your salsa.

Regardless, it is much cheaper than buying it from a store and a healthy alternative at that.

3. Is homemade salsa safe?

Yes. Using natural preservatives and following proper canning procedures, homemade salsa is safe and healthy.

4. How long does homemade salsa last?

If stored properly, homemade salsa will last about a week. Beyond that, it will need to be frozen.

5. Do I really need to purchase a bottling machine?

No. Bottling machines can be costly and not always the best choice for everyone. Instead, you can contact a contract packager to bottle and deliver your salsa. You won’t need to buy containers elsewhere if you hire contract packagers.